Matthew Martin

March 16, 2024

Karapiro’s Don Short has the fastest 50cc motorbike in New Zealand after hitting 149kph at a Landspeed NZ meet.

MARK TAYLOR / WAIKATO TIMES

Don Short hopes his dreams of visiting Bonneville’s salt flats will one day become reality, but for now he’ll settle for having the fastest 50cc motorbike in New Zealand.

At a recent Landspeed New Zealand event, Waikato’s answer to Burt Munro averaged 147kph over two runs, reaching a maximum speed of 149kph on the day – not bad for a bike with about as much power as a decent weedeater.

Speedsters on both four and two wheels have been using Goudies Rd, a former private forestry road near Reporoa (halfway between Rotorua and Taupō), to conduct their speed trials on its 7km of straight, flat tarseal for decades.

“My goal is 160kph, or 100 mile an hour, and I’m pretty sure I can reach that with a few changes to the set up,” Short said.

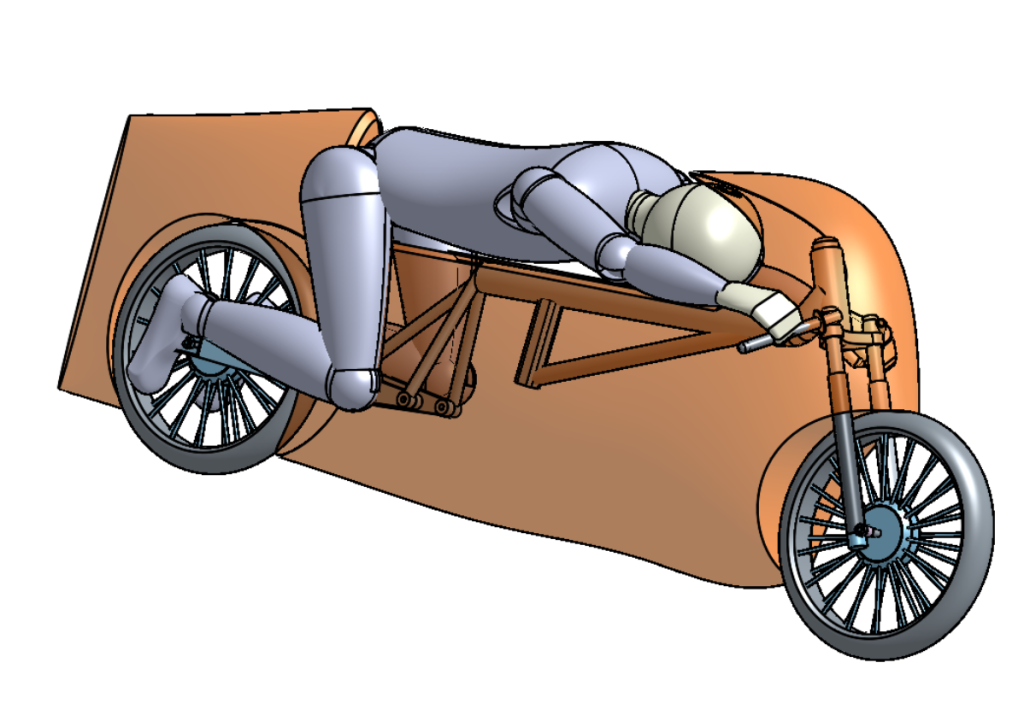

Short said the key to his bike’s speed was its aerodynamic cowling.

MARK TAYLOR / WAIKATO TIMES

“I didn’t take into consideration the altitude – about 550m above sea level – which took about 5% of my horsepower away.”

Short’s two-stroke KTM dirt bike with a six-speed gearbox produces 18hp at over 14,000RPM, but the key to its speed is its aerodynamic cowling, which was built by a friend of Short’s and adapted and refined by engineering students at the University of Canterbury.

The 55-year-old roading engineer said he always had a need for speed, but to keep his long-suffering wife happy he decided on using a smaller bike to achieve his dream.

“I picked the smallest class as it was the cheapest, and to convince my wife it was not as dangerous as riding the larger, faster bikes.”

The 50cc motor in Short’s record-breaking bike is no larger than one you’d find in a decent weedeater.

MARK TAYLOR / WAIKATO TIMES

Short literally dreams of hitting the ton (100mph) on the salt plains of Bonneville in Utah, and like Burt Munro, has pretty much done all the work himself, with some help from his friends.

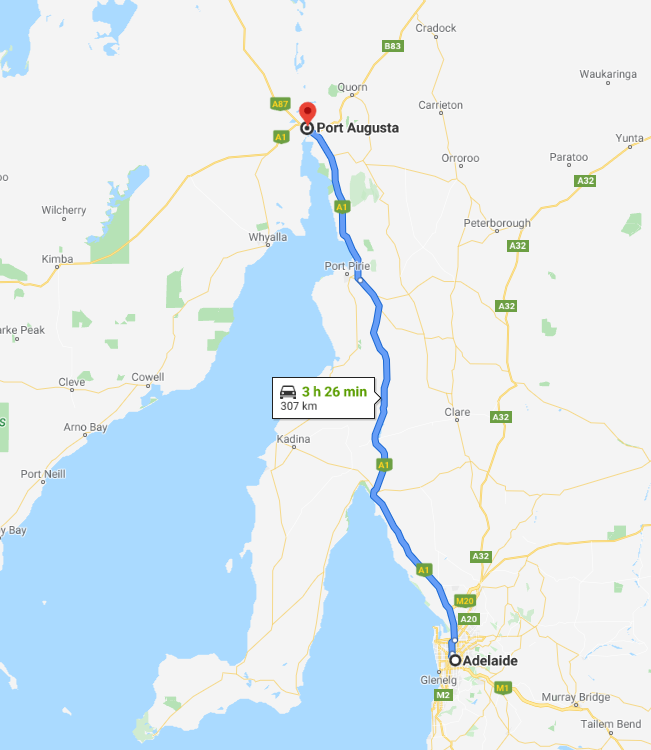

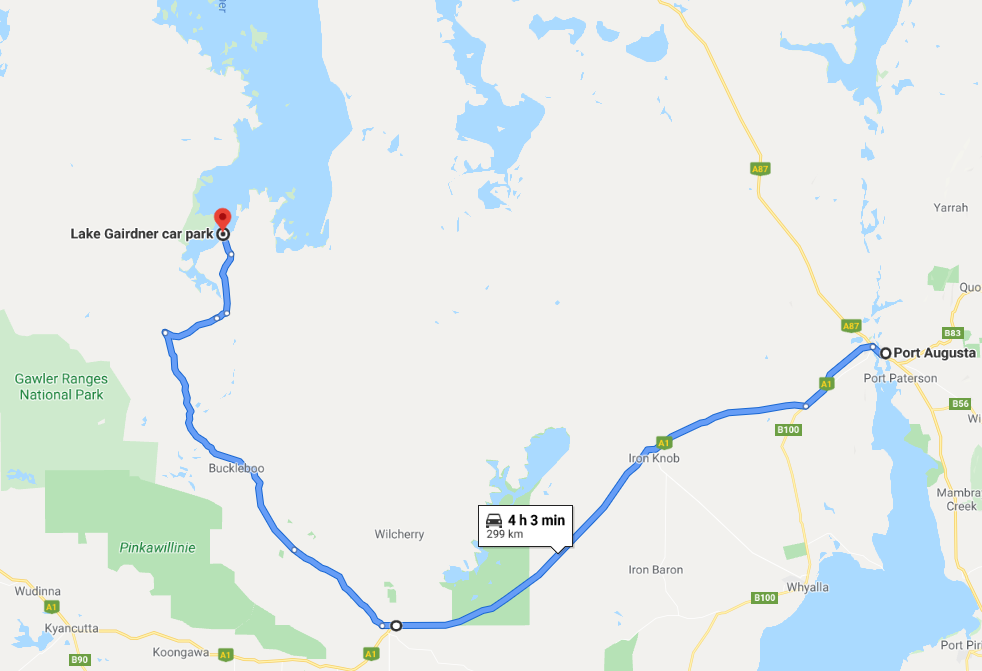

“I’ve always had a dream to go to Bonneville to watch, I do actually dream about it, and then I heard they have a Bonneville event in Australia, so I decided I’d go there to race on salt.

“This was before the Munroe movie, but I did get some inspiration from it and have watched the movie, the doco and all of that.

“I want to have the fastest 50cc bike in the world … the fastest at the moment is 233kph – but that’s a fully enclosed streamlined bike with a parachute.”

There’s not a lot of room to move within Short’s record-breaking bike, but it’s only designed to go in one direction.

MARK TAYLOR / WAIKATO TIMES

Landspeed New Zealand Association president John Seccombe said Short’s record was “official enough” for them, but to have it internationally recognised it would need to be verified by officials from the Fédération Internationale de Motocyclisme (FIM).

“It’s a bit unique what we do, but we mimic what the FIM do internationally, we just haven’t been endorsed by those international organisations.

“It’s fantastic for Don, and he now has bragging rights that he has the fastest 50cc motorcycle in New Zealand.

“All credit to him, he’s been trying a long time,” Seccombe said.

– Waikato Times

Now I just had to make them cylindrical. Andy Corrigan helped with some advice and rollers. I rolled and beat all the flat material until it became round. Then took it to a welder who welded up the seams.

Now I just had to make them cylindrical. Andy Corrigan helped with some advice and rollers. I rolled and beat all the flat material until it became round. Then took it to a welder who welded up the seams. After the seams are welded you get some deformation. So it was back to making them all round again. Then it could be fully welded into a pipe.

After the seams are welded you get some deformation. So it was back to making them all round again. Then it could be fully welded into a pipe. It came out great. Just tacked together here but very close to the finished product. It also has a stinger tube that could be replaced to change its size.

It came out great. Just tacked together here but very close to the finished product. It also has a stinger tube that could be replaced to change its size. It’s starting to look like a saltracer now. Warren did a great job from

It’s starting to look like a saltracer now. Warren did a great job from