One day I am looking at some posts from Andy Corrigan where he had published some pictures of two-stroke porn (porting photos). They were from a guy in Melbourne. I reached out to Shane Gardiner who had done the work and messages were flying backward and forwards over the next few hours.

A couple of days later I gave him a call on the phone. Like a lot of people, he was interested in salt racing but hadn’t got there yet. I don’t think he had worked on anything quite like my project.

I know very little about porting and have only one experience with modifying the exhaust port on my Suzuki A100. Every conversation we had either made sense or lined up with something I had read in one of the Two-Stroke tuning books. Along the way, Shane was able to help me discount some snake oil ideas I had been considering.

I quickly worked out that with Shane’s help this engine could go from good to great. It didn’t take much arm twisting to get him on the team. So the next minute the heart of my project was off to Victoria to get a good looking at. I gave Shane free rein with what he thought was best.

Things changed and moved a lot along the way from what I thought would be involved. I had a very simple vision of just a little bit of porting and what would be done. How wrong was I? Shane talked with me about many things and help me make decisions for the right reasons and result.

Shane ended up getting my cylinders all lined up. One of them had seen some “Dad porting” with knife-edged transfer dividers and some large ball cutter marks, cuts and radius where they didn’t need to be, probably making performance worse, not better. Shane said he would make the best of it he could. There is a lot of maths that goes into porting and if you get it wrong, your barrel can be valueless scrap.

We did price up what a new barrel would cost but at just under $800 it was out of the question.

I was also going to buy a head that you can change the chamber inserts. The problem was that the standard inserts are designed for motocross, not land speed racing. Shane said he could sort them and had some ideas. Next minute I’ve arranged for a head to be posted from the UK directly to him in Victoria. Then I start to get photos like these.

The inserts are not finished in these photos, but I’m sure you can get an idea.

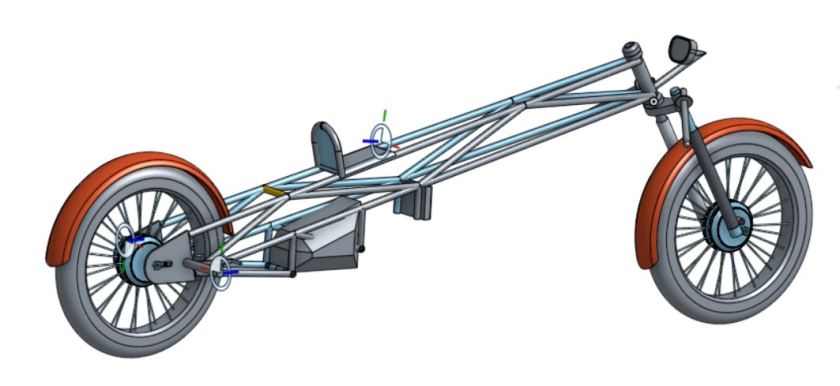

To make it all work I also need a pipe that was going to do the job. The art and it is an art of building two-stroke pipes is a dying one. I had asked around my contacts to see who could give me some advice. I was struggling.

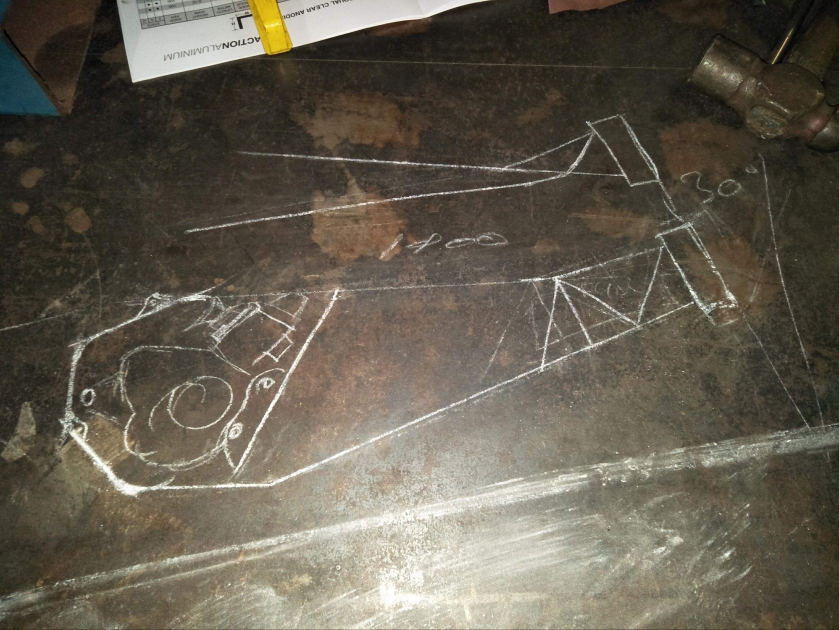

Shane offered to help out again, he drew up a design that would work with my setup with the tall gearing and rolling resistance.

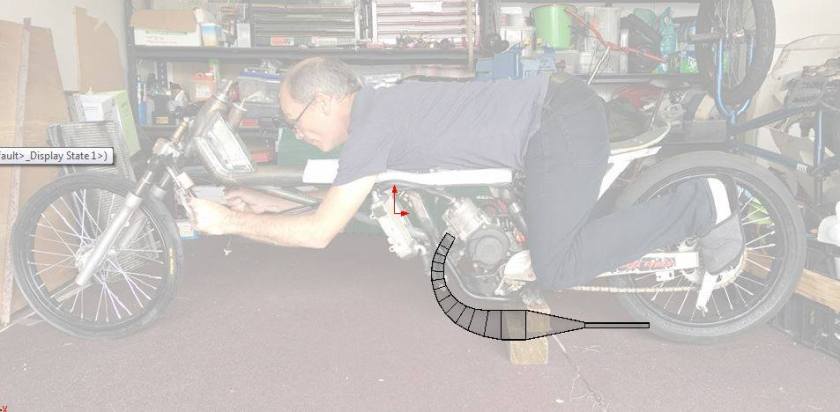

That was fine but it also had to curve so it could fit under the frame and not hit the ground. Now Shane didn’t have the bike and I didn’t have the engine so everything was done remotely with messages and photos.

He was able to come up with something that worked and would clear everything.